How Perishable Food Items are Shipped?

The dynamic chain of demand and supply necessitates the movement of goods between centres of production and demand. Transportation of goods whether they are of perishable or non-perishable nature requires careful planning and execution.

Typically, non-perishable goods are those that do not require refrigeration or special storage conditions. They last for a long time when kept under normal storage conditions.

On the other hand, perishable goods such as food items deteriorate and spoil if not stored in the prescribed temperature-controlled conditions. They have a short shelf life that can only be extended by storing under these prescribed conditions.

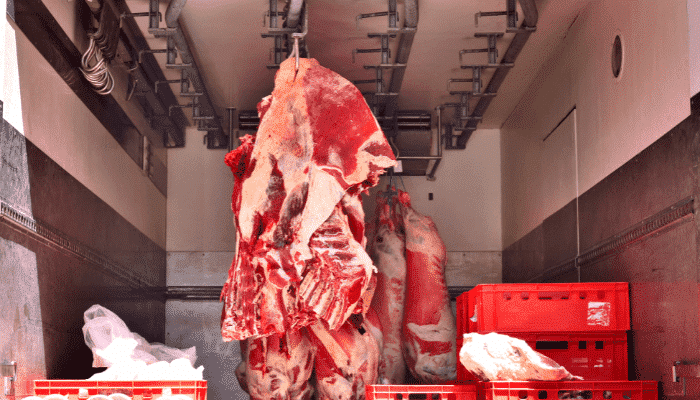

Food items such as bread, fruits and vegetables, dairy products, meat and poultry items, seafood, and pharmaceutical drugs are some examples of perishable items. They require special storage conditions and have to be transported in clean, temperature-controlled containers. This is essential to maintain the quality of these items when they are moved from their place of production to the market and the end customer.

Almost all pharmaceutical drugs need protection from direct sunlight and moisture besides a cool and dry place of storage. Similarly, some electronic equipment needs to be kept in an environment free of heat, humidity, dust, and high temperatures. Any deviation from these norms can result in deterioration and spoilage of these products before it has reached their end-life.

Shipping of perishable goods has always been a challenge in logistics. Coordinating the movement of such cargo between the supplier’s warehouse, transporter, customs and health authorities, and the customer is not easy. Any miscalculations can result in huge losses to the stakeholders.

The easiest way to transport perishable items is by the fastest mode of transport – air. However, it has its limitations. For example, air cargo transport is expensive when compared with road, rail, or sea transport and for this reason, it may not be economically viable to transport a large volume of cargo by air.

Air cargo shipped through companies without their own cargo X-ray machines have to wait through the mandatory 24 hours cooling period before being loaded onboard the aircraft. This is done for security reasons.

In spite of these limitations, transportation of several types of highly perishable cargo is carried out by airfreight.

Modern intermodal containers and temperature-control equipment have revolutionized the field of perishable cargo transport, especially perishable food items. Temperature-controlled containers are commonly known as reefers or refrigerated containers.

Refrigerated Containers

Transporting perishable cargo by temperature-controlled intermodal cargo containers, by sea, is the most preferred method when cargo volumes and the cost have to be considered. Reefers are insulated shipping containers that are equipped with portable temperature-control equipment, temperature monitoring and data logging devices.

The temperature within such containers may be set at the desired level to maintain the quality of the cargo. It may be set at low to very low temperatures as in the case of transporting frozen meat or it could be at an ambient temperature range. This would depend on the type of cargo being transported and as prescribed by the producer or manufacturer of the item.

Refrigerated containers are used to transport meat and seafood at -30°C. The same container may be used to move ambient foods items at +24°C after the necessary cleaning of the container.

Condensation

Condensation is a major cause for deterioration and spoilage of perishable goods as well as their packaging. Hence, all efforts have to be taken to ensure that condensation does not form during the loading and unloading of the cargo. This is when it is most susceptible to condensation as there is a difference in the temperatures between the warehouse and the cargo container.

It is common to pre-cool a reefer container before loading perishable food items. It is then switched off at the time of loading to prevent condensation. The container, after loading, should have enough space inside for the circulation of air. Circulation of air inside a cargo container ensures that the perishable goods inside stay fresh and the container has an even, set temperature.

In certain cases, dry containers are lined with insulated liners or vacuum panels to preserve the temperature of the loaded goods, though this might not be a very effective method for shipping perishable goods over a long distance.

Certain other key factors that have to be taken into consideration while sending perishable cargo by sea freight are given here.

Timing

Timing is very important while shipping perishable items. Waiting time at ports, waiting for customs clearance, transport, etc. have to be factored in while calculating the overall lead time. What is lead time? It is the total time taken to move your cargo between two or more locations. Lead time is a key factor in planning and forecasting.

Delays that are not factored into the lead time can result in stock expiry. This is where experienced freight forwarders come in. With their experience and contacts, many of the above-mentioned delays can be avoided.

Better routes can be chosen for the movement of perishable goods. Perishable goods with their limited shelf lives should be dropped off and picked up exactly as planned. Arrangements for their temperature-controlled storage should be made whenever a delay is foreseen or encountered.

Quality Control and Technology

The products being shipped must be clean and packages intact. Damaged or leaking packages can lead to contamination and spoilage. Besides, the container transporting such goods must be clean, especially the floor, the inside walls, and the doors. It should be free of microscopic fungi and other organisms.

A thorough cleaning ensures that the container does not have any odors that might catch on to other cargo such as food items. The grooves of the door frame must be clean and even to ensure that the door closes and seals the container perfectly.

The cold chain of perishable cargoes must be maintained throughout its journey. Various technologies such as Radio Frequency Identification (RFID), shipment tracking, etc. can be used to track a consignment and plan accordingly. Temperature and humidity sensors and monitors help to detect breakdown of refrigeration equipment enroute and take immediate actions necessary to safeguard the goods.

Instructions and Labeling

An important factor while sending perishable cargoes is to provide clear instructions to those handling the goods. Labels showing handling and storage instructions can help in preserving the quality and condition of perishable cargoes. All essential stakeholders, especially the customer, should be informed of the storage and transport conditions of the goods.

Temperature gauges may show the temperature in Celsius as well as Fahrenheit. It should be mentioned clearly whether the setting for the cargo is Celsius or Fahrenheit. Several instances of goods damages, as a result of confusion in temperature settings, are handled by insurance companies every year.

Among other things, the shipper and his service provider should discuss and decide on alternate arrangements to be made in the event of a contingency such as appropriate storage space, labor, and equipment to handle the cargo, etc.

Source: Marine Insight