What Is Energy Efficiency Design Index?

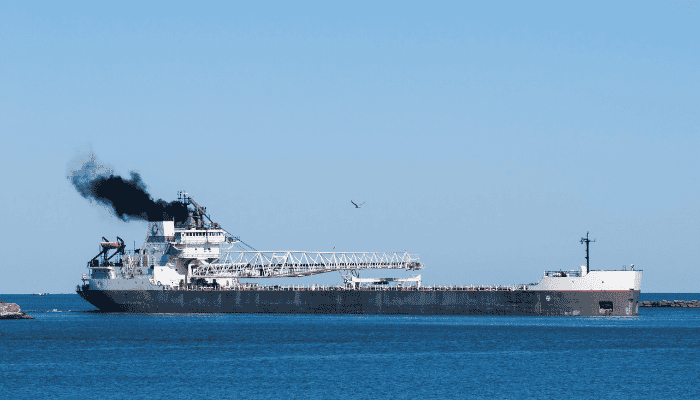

90% of the world’s trade depends on international shipping. Emissions from ships are a matter of grave concern that the most extensive transportation and logistics sector has been grappling with for several years.

As per estimates, carbon-based emissions from vessels account for 2-3% of the net global emissions. They are expected to rise manifold in the next few decades by 50-70%. Nitrogen oxides encompass a whopping 20-30% of the global share, whereas sulfurous gases contribute roughly 10% to the net emissions.

According to a report published by the American scientific research paper, large cargo vessels emit more than 5000 tonnes of sulfurous gases, whereas a petrol or diesel car emits only around 100 grams of Co2.

Other interesting statistics reveal that if the shipping sector is assumed to be an entity for calculating pollution data, it will rank sixth globally, behind the superpowers US, China, India, Russia, and Japan.

Thus, the International Maritime Organization strives to decrease maritime emissions for the prevention of air pollution by introducing new guidelines.

EEDI

The Energy Efficiency Design Index is a non-prescriptive mechanism that allows the shipping industry to use the latest technologies for designing commercial vessels as long as they meet the required energy efficiency levels and parameters.

EEDI lays down a minimum energy efficiency level, per capacity mile for different ship types and sizes. The applicable ship types include tankers, bulk carriers, gas carriers, general cargo ships, container ships, refrigerated cargo carriers, and combination carriers.

In 2014, EEDI regulations were amended by MPEC. These extended its scope to LNG carriers, vehicle carriers, ro-ro ships, and cruise passenger ships having hybrid propulsion systems or non-conventional propulsion.

Energy Efficiency Design Index and SEEMP were formulated by IMO as amendments to its interim guidelines MARPOL ANNEX VI at the 62nd Marine Environmental Protection Committee meet ( Resolution MEPC 62) in 2011 and enforced from January 2013 onward. These guidelines were also approved by the Marine Environment Protection Committee.

From 1st January 2013, newly constructed ships had to meet the level for their ship type. The carbon dioxide reduction level for Phase I is 10%. Every five years the EEDI level would become stricter to boost innovation and technical development and reduction measures, ultimately influencing the fuel efficiency of a vessel right from its design phase or the initial design stage. Reduction rates were set until 2025. By adhering to this guidance, the shipping sector can be less polluting.

This measure was applied to all new vessels above 400 GT, partially built ships, and construction orders after January 2013.

EEDI Components

It is estimated using the EEDI formula which calculates the vessel’s Co2 emissions per unit of transport work done while in service. Now, this EEDI has two components: 1) Attained EEDI. 2) Required EEDI.

A complex formulation is used for calculation and verification of the vessel’s attained EEDI based on technical factors related to the type, cargo capacities, ship speed, hull type, main engine, turbine, propulsion, fuel, service information, dwt, etc.

EEXI

EEXI is another historic milestone fostered by IMO after the adoption of EEDI. It highlights the vessel’s emission rate and its propulsive efficiency. It is then compared with the Required EEDI, calculated on empirical and statistical relations as mandated by IMO and other classification bodies based on vessel data and pollution scenarios.

For all practical purposes, the attained EEXI needs to be lesser than or at most equal to the Required benchmark. If somehow, this attained value exceeds the required, the vessel is said to fail in terms of energy efficiency and is not deemed fit to ply in the seas.

Now, a natural question arises: If such norms exist for new vessels, what about existing ships, which as a matter of fact, emanate more amount of pollution due to their age as compared to new ships? Though somewhat late in its advent, EEXI is an answer to that.

The Energy Efficiency Existing Ship Index (EEXI) concept was broached up in the MEPC 75 of IMO held in 2020 with an agenda to make significant changes to the crucial Annex VI.

This development is seen in the wake of the IMO’s ambitious Greenhouse Gas Strategy (GHG) of 2018, which sets a massive target of curtailing ships’ carbon emissions up to 40% by 2030 and 70% by 2050. It also aims to reduce all toxic greenhouse gas emissions by 50%, compared to the reference emission levels of 2008.

The final target is to achieve the idealistic zero emissions towards the end of the century. While it may look unrealistic, many view it as a crucial game-changer in assuaging the effects of transport emissions. Even if strict numbers do not achieve the target, it can improve the scenario dramatically in the coming decades.

The main objectives of MEPC 75 were to introduce two crucial pillars: EEXI and Carbon Intensity indicator, the CII. EEXI is essentially a technical measure, and CII is an operational measure. In the 2021 MEPC 76 and 77, the EEXI guidelines and regulations were detailed and will be enforced by January 2023.

For all practical purposes, EEXI is the same as EEDI, with one difference. The former is applied to all existing ships above 400 GT. Exceptions include FPSOs, Drillships, and Polar vessels. The estimates for EEXI are almost the same as EEDI.

Formulation of EEXI

Like EEDI, Attained EEXI needs to be less than or equal to Required EEXI. The formulation of Attained EEXI varies from vessel to vessel, of course and can be simply summarised as the carbon emissions per unit weight and unit distance traveled.

In concept formulation, this may be written as:

Attained EEXI = (Carbon Dioxide conversion Factor X Specific Fuel Oil Consumption of Engines X Engine Powers)/ (Cargo or tonnage capacity X Speed).

The carbon dioxide conversion factor is based on the grade of fuel oils used. Specific fuel consumption is the amount of fuel expended in-unit work (this is obtained by the power generated in kW multiplied by time).

For all practical purposes, the capacity or tonnage is taken as the deadweight, with only one exception for containerships, where it is to be taken as 70% of the net deadweight. Similarly, speed and engine power are to be calculated at 75% of the maximum power rating of the engine(s). The detailed formula, calculation of the individual terms, and other variables associated with factors and conditions based on vessel scenarios are beyond the scope of this article.

Like EEDI, the Required EEXI is based on empirical reference lines for the vessel. If attained is within the required limits, the ship is said to be EEXI-compliant. If not, then non-compliant.

Implementation of EEXI

- As a first step, EEXI compliance is assessed for the vessel. If complied, an EEXI Technical File is prepared. This file includes all relevant documentation and technical details, including EEXI estimation and compliance procedures, measures, and practices being followed for vessel performance.

- This is then submitted to the concerned classification society for approval. An overview of the file is carried out along with a survey and re-evaluation of the compliance status.

- Once class approval is cleared, an International Energy Efficiency Certificate (IEEC) is issued, and the vessel is deemed fit to be in service in terms of energy efficiency.

- If the EEXI compliance fails in the first place, various ways to improve on the EEXI are carried out. After adopting these measures, the above steps are carried out again if the vessel satisfies the compliance requirements.

Ways to improve the EEXI of a vessel

Now, for all existing ships, the main concern is attaining EEXI compliance, at least from January 2023 onwards. If it fails, the vessel is deemed ‘unfit’ and is thus not allowed to sail as per statutory requirements. From a technical point of view, the main crux of improving on the attained EEXI is reducing the index of emissions and, if required, fuel consumption as well.

This can be done in the following ways:

- Retrofitting Energy Efficient Technologies involves incorporating new technologies and systems to reduce or improve emissions. They are quite expensive.

- Operational Power Limitation: EPL or Engine Power Limitation is one of the easiest ways to meet EEXI requirements for older ships because it demands minimal retrofitting changes to the vessel and does not affect the engine. EPL caps a limit on the capability of the machine in terms of its power and speed. Engine Loads are practically proportional to the cube of the vessel service speed; therefore, a drop-in operating rate by 10% reduces fuel consumption and related emissions by 30%.

- Traditional means regulate the fuel entering the engine in mechanically-controlled engines (stoppers and physical means) and electronically-controlled ones (automatic fuel limiters). Exceptions for EPL are adverse weather conditions and difficult situations where the ship may require high engine power. This may not be effective if the vessel operates at slower speeds. So, the efficiency measures must be adequately re-evaluated in tune with the GHG policy.

- Switching to alternate and lower carbon fuels is also a viable option.

Frequently Asked Questions

1. What is the energy efficiency operational index?

Energy Efficiency Operational Index is an effective measurement indicator used for assessing the ship’s energy efficiency and CO2 emissions toward the environment.

2. What is the purpose of the energy efficiency design index?

It calculates if a vessel is energy efficient, given the norms and regulations of IMO. It is based on a formula that considers technical parameters including the ship’s emissions, capacity, speed, etc. The lower the vessel’s EEDI, the more energy efficient it is and vice versa.

3. How is EEDI Calculated?

Required EEDI = a.b-c, where a list is used to determine the ship type dependent on calculation values for required EEDI. The EDI will be decreased by X % every five years based on the initial value and according to vessel size. Below a certain size, no reduction is applicable.

4. How to reduce EEDI?

EEDI can be decreased by reducing hull resistance which lessens the power needed for propulsion. It can be attained by increasing the strength of the hull, beam, or both, adopting a slender design without altering the vessel’s cargo-carrying capacity.

5. What are EEXI and CII?

EEXI indicates the technical efficiency of a vessel and applies to ships weighing over 400 Gross Tonnes and operating in International waters. CII measures the ship’s carbon intensity, thereby recording the operational efficiency of the vessel over a period of time.

Source: Marine Insight