Functions of a Warehouse – A Detailed Guide

Warehouses in the olden days were used purely for the storage of goods. They were usually large buildings located near railway junctions, ports, or business centres.

These warehouses were given on rent wholly or partially for storage of goods, machinery, etc. with the customer having to arrange all activities such as unloading, loading, and packing of their cargo.

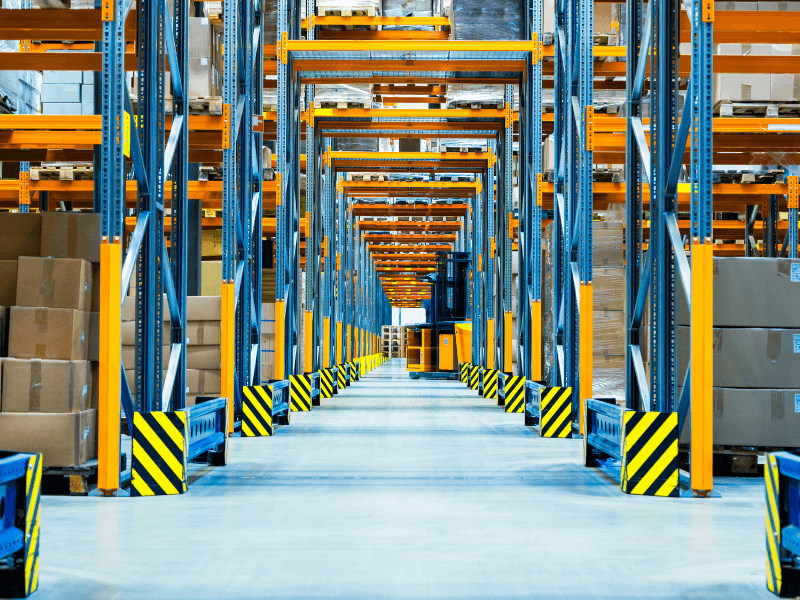

Gone are those days when a warehouse meant strictly ‘storage space only’. Most modern warehouses are architectural and technological wonders that cater to almost all the supply chain requirements of its customers.

A supply chain includes all the stages a product passes through, from its production until it reaches the hands of the end customer. Warehousing is an integral part of the modern supply chain and logistics operations. It is where most of the operations take place.

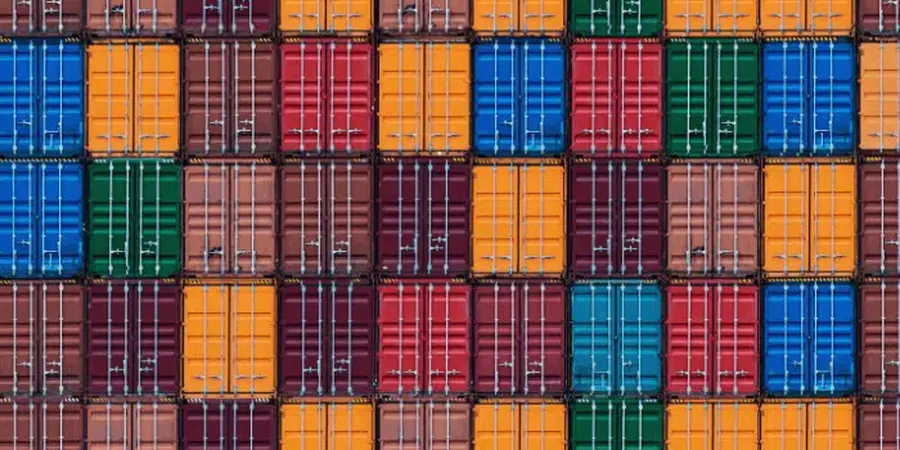

According to 2020 data released by the World Trade Organization (WTO), 17.5 trillion USD worth of goods were exported between countries (this is USD 2 trillion less compared with the figures of 2019, as a result of the slump in trading activities caused by the Coronavirus pandemic). As we can see, this does not include goods sold within countries.

The supply chain of the goods thus traded would have included its storage at some point in time. Imagine the warehouse infrastructures required to hold and handle this whopping quantity of goods!

Are Warehouses Necessary?

The simple answer to this is Yes. Warehousing of goods becomes a necessity due to the time gap between production and demand.

Even goods that are made on demand have to be stored for a brief period. The facility to store goods allows companies to produce or manufacture their products in advance to meet future demands.

For goods with seasonal demand, storage is a necessity. They are produced in advance and warehoused to meet future demand.

Economies of scale require production in prescribed large numbers that cannot be sold to customers all at once. Such goods have to be stored until there is demand for them. Temperature-controlled warehouses cater to the needs of storing ambient, chill, or frozen goods.

Classification of Warehouses

Warehouses may be broadly classified as government-owned, owned by private companies, or by cooperatives.

Bonded warehouses are either run by the government or licensed to private operators by the government. They allow storage of goods without having to pay customs duty until these goods are taken out of the bonded warehouse.

Bonded warehouses are usually used for the storage of high-value imported items such as alcoholic drinks, tobacco, certain electronics, etc.

Requirements of a Modern Warehouse

Besides a convenient location, good accessibility by road, availability of space, and the latest material handling equipment, a warehouse should be designed in such a way that receipt of goods, inspection, storage, issue of goods, and other functions can be done easily.

To avoid bottlenecks inside the warehouse, the Material Flow Planning (MFP) has to be perfect. Material flow may be planned, based on the U-Flow or Through-Flow methods.

In the U-Flow method, goods flow in the shape of ‘U’ through the warehouse. The receipt and dispatch of goods happen at the same side of the warehouse building with the same docks being used to receive as well as dispatch goods.

In the Through-Flow method, goods flow from one end of the warehouse building to the other, often in a straight line. To simplify, goods are received at one end of the warehouse, taken inside for storage, picked, and dispatched from the other end.

The layout of a warehouse has to be planned properly before construction, taking into consideration the following main factors:

- Fire-fighting equipment

- Sufficient spacing – aisles, passages, etc.

- Sufficient space to manoeuvre modern material handling equipment.

- Ventilation and lighting

- Heating and refrigeration systems

- Office space

- Provision for future expansion of the facility

A good layout design is critical for the maximum efficiency and space utilization of a warehouse.

The Main Functions of a Warehouse

Warehousing is a key component of any supply chain. Let us take a look at the main functions of a warehouse that usually starts with the receipt of goods.

Unloading

Goods are delivered to a warehouse usually by road transport. Such goods are referred to as Goods Inward. Whether it comes by cargo ship, aircraft, or goods train it has to be moved to a warehouse, however, close it might be to the quayside, runway, or train station using a truck or other suitable vehicle.

The operations manager of the warehouse has to plan and ensure that the resources and arrangements to receive such goods are made in advance. This is called a Goods Inward Plan (GIP).

It may be necessary for the warehouse to arrange for the vehicles to shift cargo from the seaport, airport, or railway station. Staff to unload the goods inward have to be assigned and the necessary material handling equipment made available.

Goods that have come in are unloaded at the warehouse and arranged for an inspection.

Inspection

The warehouse operations staff have to ensure that what is shown on the packing list is what is actually received at the warehouse. The packing list and the invoice should also match. A goods receipt inspection includes, but is not limited to checking that the quantities are correct, prices shown are accurate, and that there is no damage to the goods or deterioration in quality when received.

Any inaccuracies or other issues should be documented and brought to the attention of the operations supervisor who would then take it to the attention of the stock administration staff. The stock administration staff informs the shipper, the transporter, or the insurance representative of such issues.

Once unloading and inspection of the goods are completed the warehouse operations staff prepares an Inventory Receipt Report (IRR) by consignment. The IRR would show details of the goods received including details of goods received short, excess receipts, expired or damaged goods received, and other such information.

Put-away and Storage

This is the stage when the goods that are received and inspected are moved to their respective system allocated locations on racks inside the warehouse. Very seldom is block-stacking followed in warehouses these days.

In block-stacking, loads are placed on the warehouse floor and stacked on top of each other to a stable height. While it saves space, it can be quite cumbersome to handle.

The IMS allocates locations for the goods inwards based on put-away rules as decided by the warehouse management. Goods for put-away are normally identified using bar codes. Bar codes are computer-readable. Bar code scanners convert the data into readable information such as product and package information, location, etc.

The IMS works out a pattern of storage whereby the stored goods can be accessed easily for later distribution based on the principles of FIFO (First In – First Out), FEFO (First Expiry – First Out), LIFO (Last In – First Out), etc.

Some warehouses use light technology where a system-controlled light guides the operator to the exact location to place the goods. A Put-away report shows the goods that have been received into the warehouse with their respective details and location in the warehouse.

Systems Receipt

Once the put-away of goods is completed, the received quantities are accepted in the warehouse Inventory Management System (IMS). The Stock Administrators of the warehouse are usually responsible for this. They will account for the exact quantities received, at the agreed prices, taking into account short receipts, damaged stocks, etc.

The output here is usually in the form of a Goods Receipt Note (GRN). Typically, with the issue of a GRN, the specific goods are available in the computer systems for re-distribution or sales.

Issue of Stocks

Stocks are issued from a warehouse based on orders received from their customers who could be internal or external. Stocks that are issued are known as Goods Outward.

Most IMS are designed to automatically uploaded orders into the systems for processing. Once orders are uploaded, the system detects out-of-stock items and generates a Pick List (PL) for the remaining ones showing the locations from where they are to be picked by the operator.

Similar to the technology used for put-away, light-based technology may be used to guide the operator to the exact location to pick the goods. Based on the final Pick List, an invoice or Goods Issue Report (GIR) is printed.

The stocks thus picked are moved to the loading area as per a loading plan. A Daily Loading Plan (DLP) is prepared by the operations supervisor taking into account the total number of orders to be dispatched for the day and the priority of each order. The required trucks or truck trailers have to be arranged for the transport of these goods and staff assigned to handle the loading functions.

Documentation

Goods that are taken out of the warehouse for delivery or dispatch have to be supported by their proper documentation. Invoice, packing list, shipping documents in the case of goods for export, clearance from Road Transport authorities in certain cases, etc. are just a few of these. These have to be collated and kept ready for the driver of the truck transporting the goods.

Cross Docking

Also known as Dock-to-Dock, cross-docking is a very productive method of transporting goods between locations without having to make use of intermediate storage. In this method, instead of storing the goods, they are checked and immediately loaded onto a mode of transport for direct delivery to the customer.

Cross-docking is carried out from a warehouse marshalling or staging area. This is the area where goods are assembled temporarily during their receipt or dispatch. In some cases, it may also be done from the port/airport/railway yard and sent directly to the customer. Cross-docking is usually done when goods are transported from the supplier to the distributor. It saves time, effort, and money.

Stock Counts

Warehouse stock counts or stock-takes help to confirm the accuracy of stocks held in the warehouse. In other words, it checks whether the stocks as per physical count match with the stock of goods according to the system, at a given point in time.

Generally, an annual stock count is a legal requirement for a registered business. It may also be conducted quarterly or half-yearly. Periodic stock counts help to spot errors or issues such as pilferage etc. Discrepancies that are found during a stock count are later corrected or written off after approval by the authorized manager.

Pest Control

Pests cause stock losses amounting to several billion US dollars every year. All warehouses have to be disinfected at regular intervals to prevent damages caused by vermin, rodents, or other pests. The damages caused by these creatures can result in major losses, both to the stocks as well as the warehouse infrastructure.

For example, rodents may gnaw into the wiring of machinery, or plastic and wooden parts, causing fires or other serious accidents. Fumigation, traps, poison baits, etc. are some methods of pest control.

Other Value-added Services

Warehouses often provide value-added services to their customers to retain them as well as attract new customers. Some of the value-added services include packing, labelling, documentation, and other such services.

Warehouse Security

Goods that are stored inside a warehouse and the warehouse infrastructure may be worth millions and require security from damage, pilferage, theft, arson, etc. Warehouses have an obligation to safeguard the goods that have been entrusted in their safekeeping by their customers.

CCTV cameras, motion sensors, alarms, and effective patrolling in and around the warehouse periphery are essential for the safekeeping of the property and goods. A large warehouse may have a security manager to look after such matters and to liaise and maintain a good rapport with the local police force, fire station, and other local authorities.

Insurance

Insurance cover is normally taken by the warehouse management for the stored goods as well as the warehouse infrastructure and all other equipment. There are various types of insurance for warehouses. These include partial as well as comprehensive insurance to cover incidents like fires, floods, and other types of losses.

However, it will have to be established that the loss was caused despite the warehouse having taken all possible measures to counter these. The customers may also take insurance on the goods owned by them.

Machinery and Equipment Used in Warehouses

Machines and equipment are used in warehouses and yards for the safe and efficient handling of goods and materials in bulk or as separate smaller units. These are known as Material Handling Equipment (MHE). They help to load and unload goods (goods outward – goods inward), move heavy cargo between locations, etc.

Examples of material handling equipment are forklifts, cranes, pallets, heavy-duty sheets for covering goods, etc. A warehouse manager has to ensure that all MHE are serviced according to their prescribed service intervals and maintenance contracts are in place.

Modern warehouses are designed to ensure the maximum efficiency of their operations. Such warehouses have the latest equipment and software such as an Inventory Management System (IMS) to optimize their inventory-related processes. The IMS is often integrated with an Enterprise Resource Planning (ERP) system to bring together the different functions and departments, thereby enhancing the organization’s system capability.

However, qualified and efficient staff are the backbone of any successful logistics operation. How much ever automation and digitalization that may have come in recent times, efficient staff to handle these is of great importance.

In an industry that is dictated by fierce competition, warehouses that make use of the latest trends in technology and which are run by efficient managers and staff are always the front-runners.

Please note that what we have mentioned in this article are some of the main features and functionalities of a modern warehouse.

There may be warehouses that are equipped with other latest and customized equipment. Warehouses may also offer facilities and services to their customers, other than what is mentioned here.

Source: Marine Insight